In a floating ball valve, the ball is not rigidly held on its rotational axis. In the closed position, the ball is pushed against the seat by the pressure of the fluid from upstream and hence can pressure seal the downstream of the valve.Ball seats on the downstream seat only.the ball is suspended in the flowing fluid and is kept in position by the compression of two elastomeric seats against it.

The ball shaft is connected at the top of the ball and allows the switch from an open to a closed position with a quarter turn movement. When the shaft is turned, a load is applied to the ball which gets pressed against its seats.This design, which is lightweight and economic, suits bore sizes up to 10 inches: above this bore size, the seats of the valve would not be able to withstand heavier and heavier balls and the valve would not operate safely and efficiently.

The Floating ball valve has a lower manufacturing cost, and it allows a bi-directional shut-off of the flow (as the trunnion type).

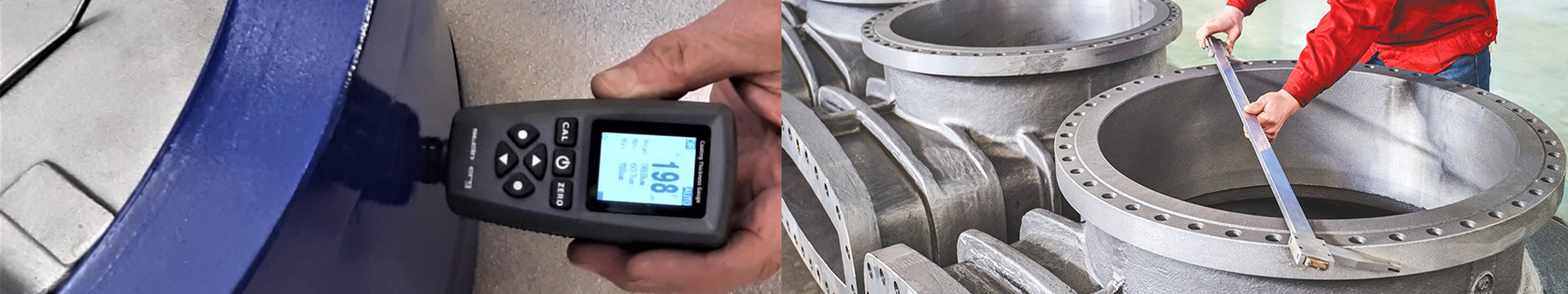

Floating Ball Valve-Drawing

Floating Valve

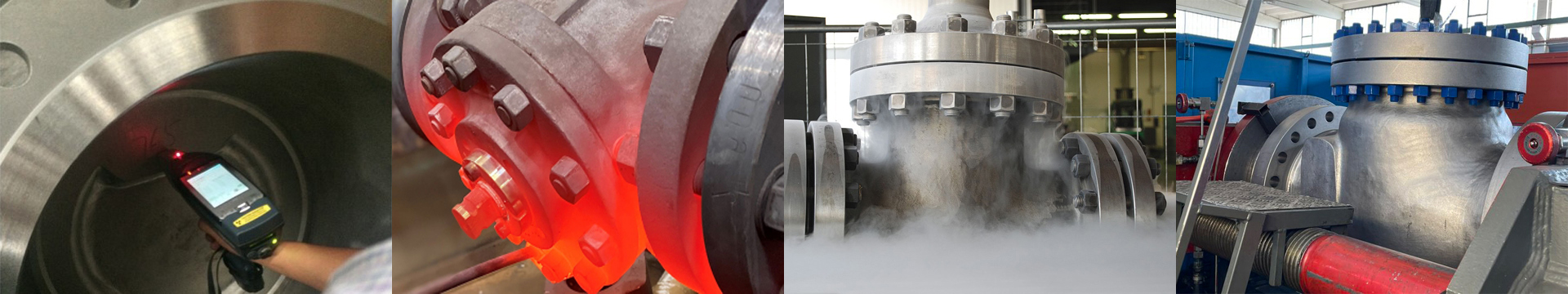

Seat Suppored Floating Ball Valve