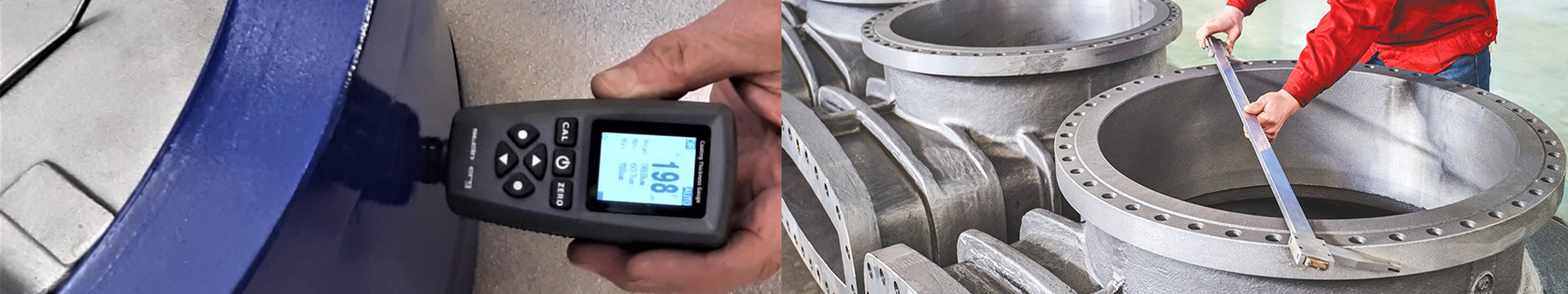

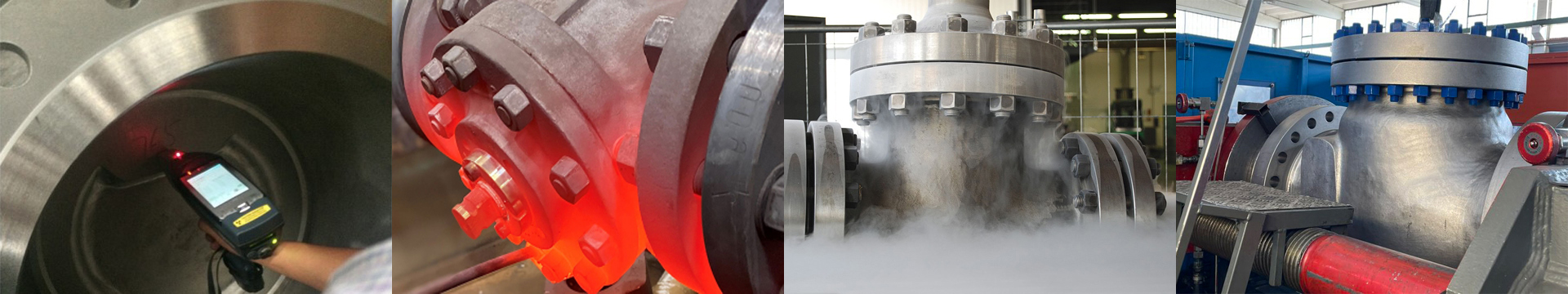

Knife gate valve is designed mainly for on-off and isolation services in systems with high content of suspended solids. In the industries like pulp and paper flowing fluid inside piping system is very thick. The normal valve will not be able to accurately stop the flow and there was always some leakage. Knife gate valve is designed to the world to solve these issues in industries working with high viscous fluid. Knife gate valve was first produced in 1927 and since then it is widely used all over the world. Knife gate valves are especially beneficial for handling slurry, viscous, corrosive, and abrasive media. The valves have a minimized pressure drop in the fully open position, they are easy to actuate, they have a relatively low weight, and are cost-effective.

The closure element of a knife gate valve is built with sharp edges to cut through high dense material flowing in the pipe, that is why it is called knife gate valve. To stop the flow when required this valve uses the pressure drop function. This ensures that the valve is perfectly sealed and no leakage.Knife-shaped gate of knife gate valve Cuts through the tough or sticky material. It also ensures that any excess material is not being stuck between the valve components. This also assure that excess material will not create any cleanliness issues.

In the industries like pulp and paper flowing fluid inside piping system is very thick. The normal valve will not be able to accurately stop the flow and there was always some leakage. Knife gate valve is introduced to the world to solve these issues in industries working with high viscous fluid.

Stainless Steel Knife Gate Valve

Knife Gate Valve

Knife Gate Valve Drawing