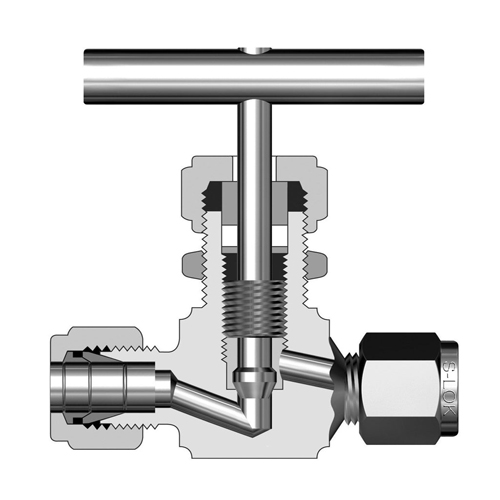

A needle valve is a type of valve with a small port and a threaded closure element. They get their name needle valve from their needle-shaped conical disc and matching seat. The working principle of needle valve is similar to the globe valve in design with the biggest difference is the sharp needle-like disc.

Needle valve is linear motion valve. Because of the needle valveconstruction and plug shape, needle valve is designed to make very accurate control of flow in small diameter piping systems. It allows precise regulation of fluid flow, although it is generally only capable of relatively low flow rates and has a relatively large pressure drop from the inlet to the outlet.

Needle valves open and close an orifice with a tapered end that raises and lowers with the spin of a handle.The handleis connected to the plunger, also called a stem. Once turning the handle, the plunger moves up or down based on the threads. The locking nutprevents it from fully unscrewing. As the plunger moves down, the tapered pointed endcontact with the valve seat to fully seal the orifice. Commonly, the valve seat is also tapered. There are various options and sizes available to connect it to a pipe or hose through the port connection on the input and output. The bonnet is connected to the valve housing, which can be made from different materials like brass or stainless steel.

Regular port size for needle valves range is from 1/8” up to 2”, thus needle valves are used widely in instrument systems.

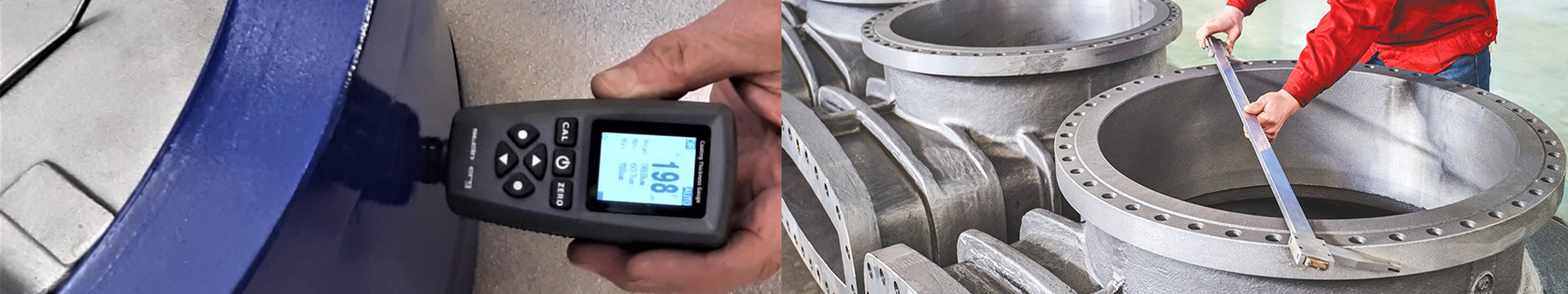

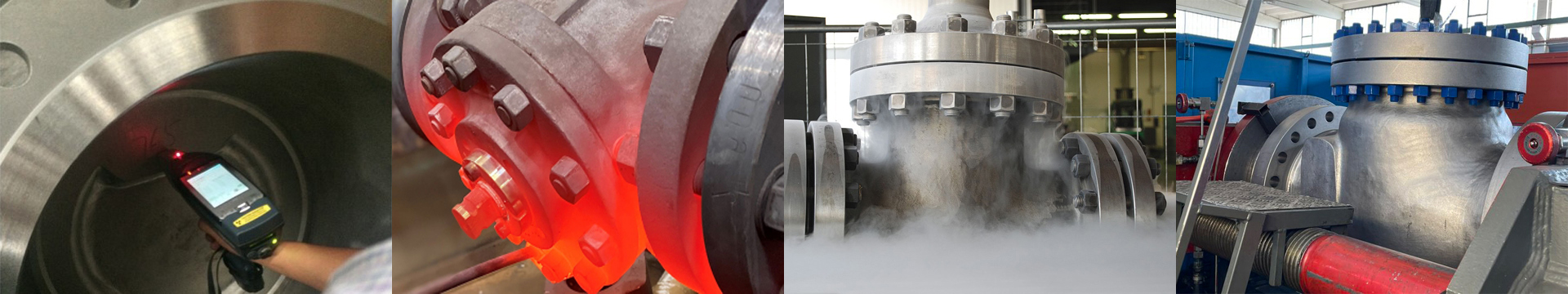

Needle Valve

Needle Type Valve

Needle Valve Drawing