A wafer type valve means the valve will be installed between the piping system in the wafer type. The valve is designed to clamp between two flanges in pipe work. So the valve should have sealing face, the rubber or EPDM valve seat creates an exceptionally strong seal between the valve and flange connection.Wafer style flange connections are typically reserved for butterfly valves due to their slim profile. But they also could be found on ball valves and check valves.

This connection type simply squeezes the valve between 2 flanges using long bots or threaded end rods. There are holes on the valve for the bolts to pass through, which are not threaded. There is not always a hole for every bolt hole on the flanges. They are simply used to help hold the valve in place until all the other bolts are in. On resilient seated butterfly valves, the resilient seat is also used as the seal between the valve and flat-faced flange on each side. On high performance butterfly valves, raised face flanges are used along with gaskets to form a fluid tight seal. This type of connection is not suitable for dead end service.

Wafer Check Valve

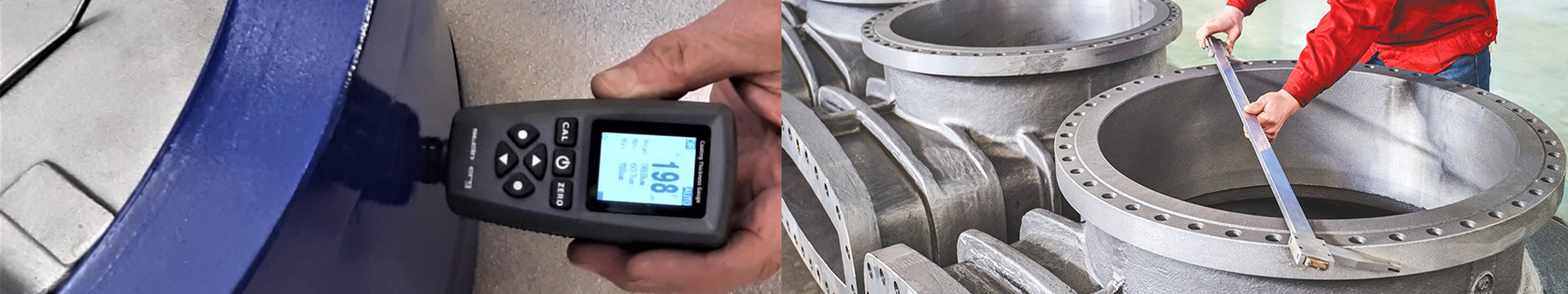

Wafer Ball Valve

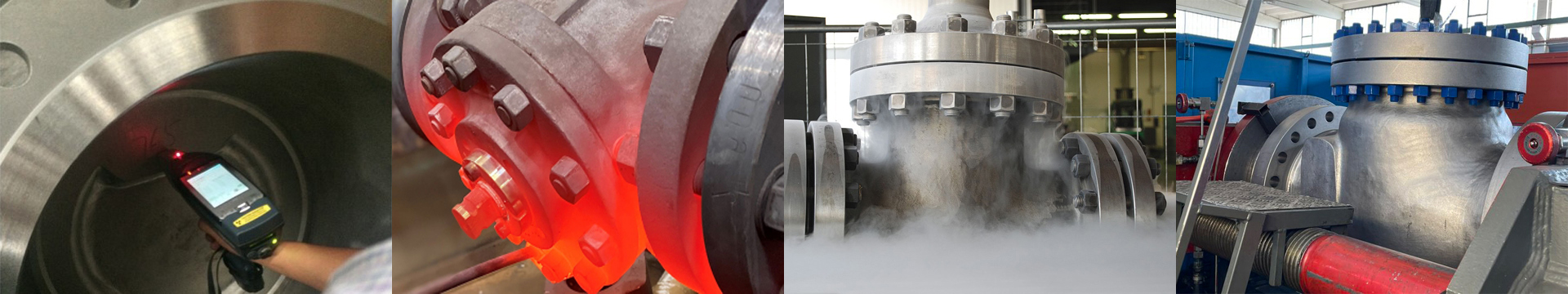

Wafer Butterfly Valve