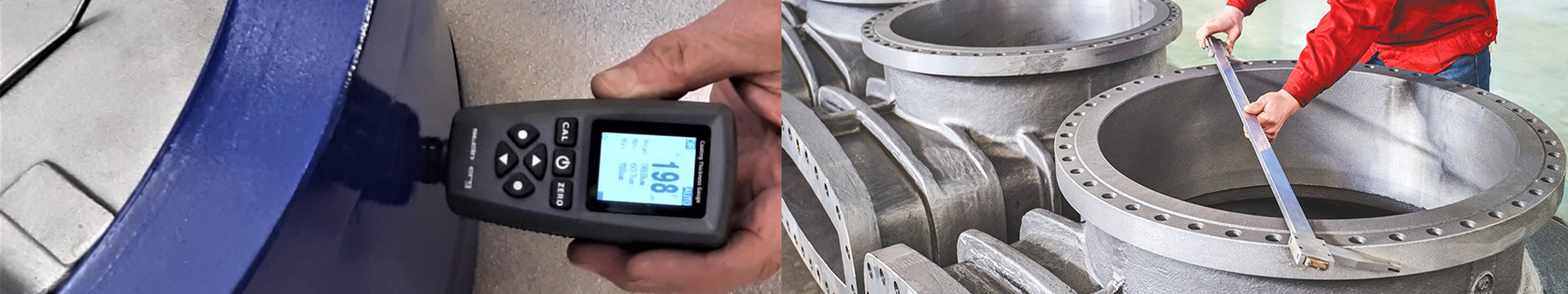

Check valvemeansthe valve that opens with fluid movement and pressure, closes to prevent backflow of the pressure to upstream equipment including pumps and compressors, where back flow could damage the internals of the equipment and cause an unnecessary shutdown of the system and in severe cases the complete plant.Check valves allow fluid to flow in only one directionin a piping system. They have two ports: one as an inlet for the media and one as the output for the media. Since they only allow media flow in one direction, they are commonly referred to as ‘one way valves’ or ‘non return valves.

Check valves are automatic valves and unlike other valves, human intervention or external control is not required for their opening or closing, so mostlythe check valve do not have any valve handle or stem. Check valves are powered by the fluid flow and the pressure difference that exists between their inlet and outlet ports.The only purpose of the check valve is to prevent flow reversal or back-flow and they are available in various sizes, designs, and materials.

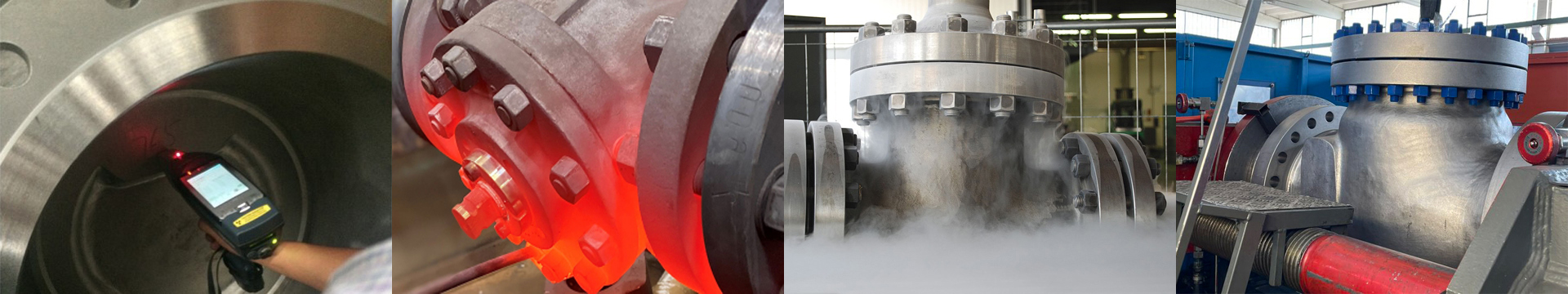

Check valves may be grouped according to the way the closure element moves onto the seat. there are several types of check valve as following:

Swing Check Valve, Wafer Check Valve,Piston or Lift Check Valves, Ball Check Valve, Tilting-Disc Check Valve, Diaphragm Check Valve, Stop Check Valve, Spring Loaded Check Valve, Duckbill Check Valve.

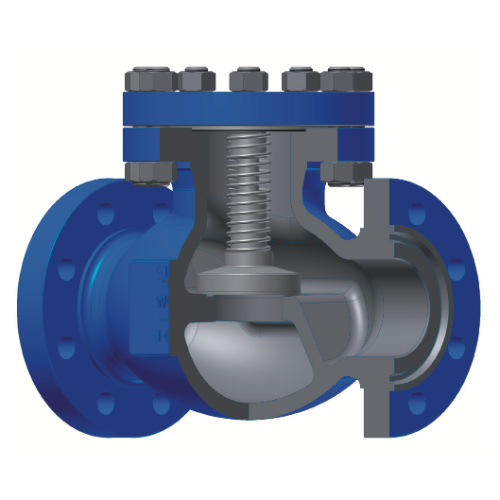

Check Valve

Disc Check Valve

Lift Check Valve